Exciting NEWS:

Toollense Type V – PureVision

Toollense Type E:

An inspection machine this cheap?

… it can’t be good!

… or can it? Let us convince you.

For those who expect more:

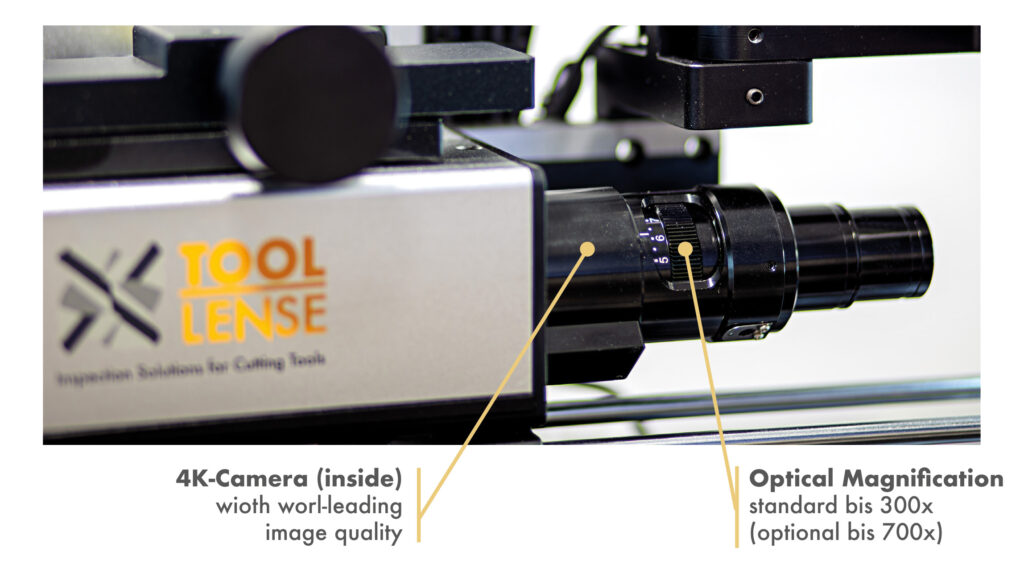

Unbeatable Image Sharpness

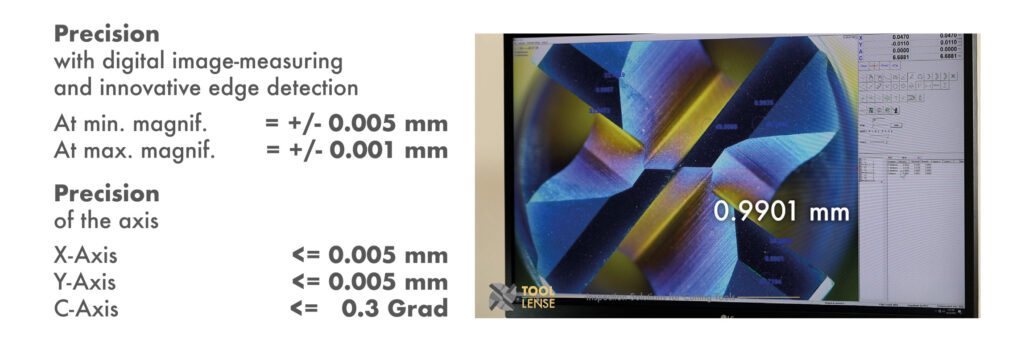

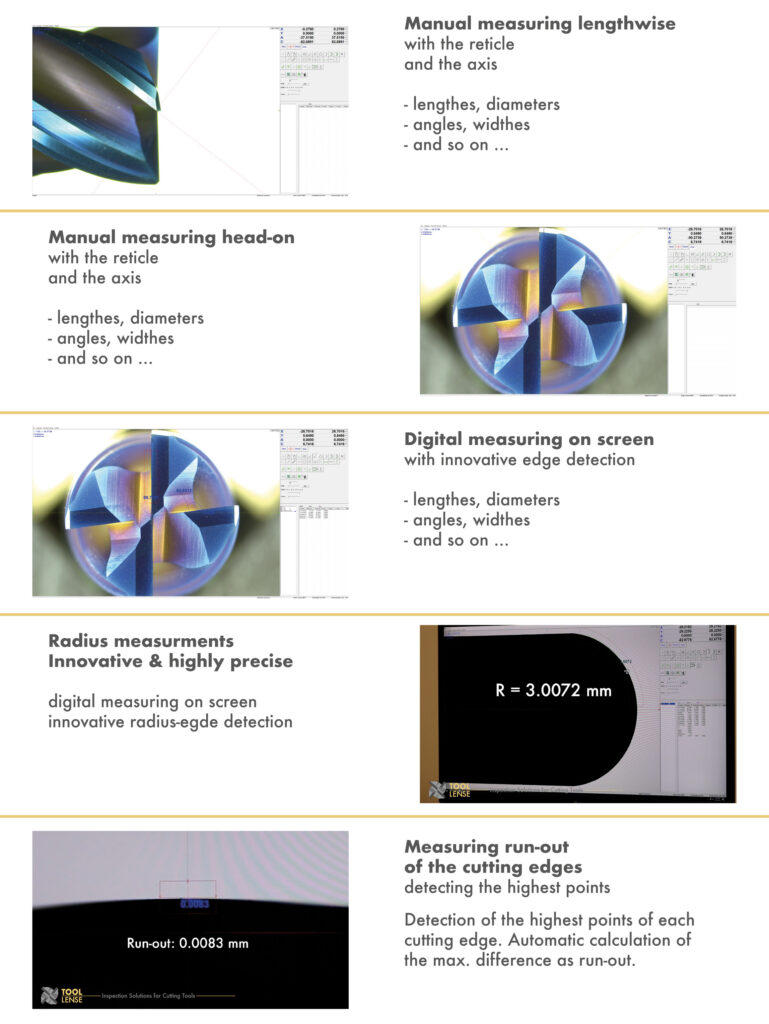

Only those who see clearly can measure precisely. Our 4K camera, equipped with high-quality optics and precise zoom, captures every detail – for accurate and reliable measurement results.

Magnification up to 300x (standard)

Alternatively, machines with magnification up to 1000x are available – whether 300x, 500x, 750x, or the maximum: with Toollense, even the smallest micro-tools can be inspected accurately and reliably.

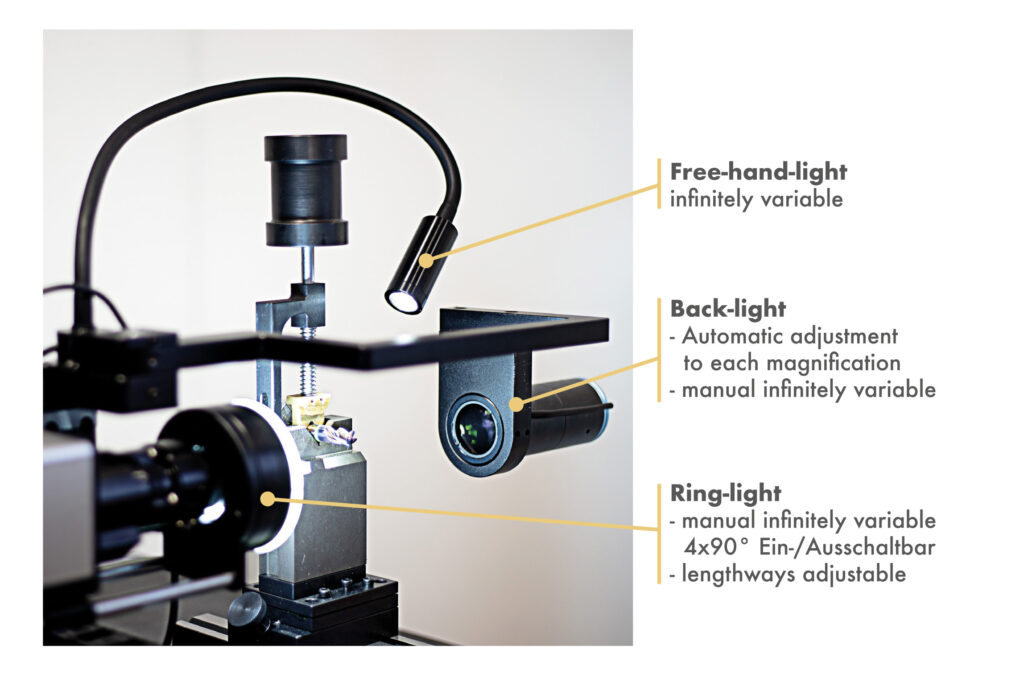

Never measure incorrectly again

Automatic Zoom Recognition – the Toollense software automatically detects the selected zoom and perfectly adjusts the lighting. This way, precision becomes standard.

Intuitive and User-Friendly Software

Our intuitive and user-friendly software enables anyone to perform precise measurements quickly and easily. With a clearly structured user interface and simple functions, measuring becomes a breeze, regardless of experience or technical background.

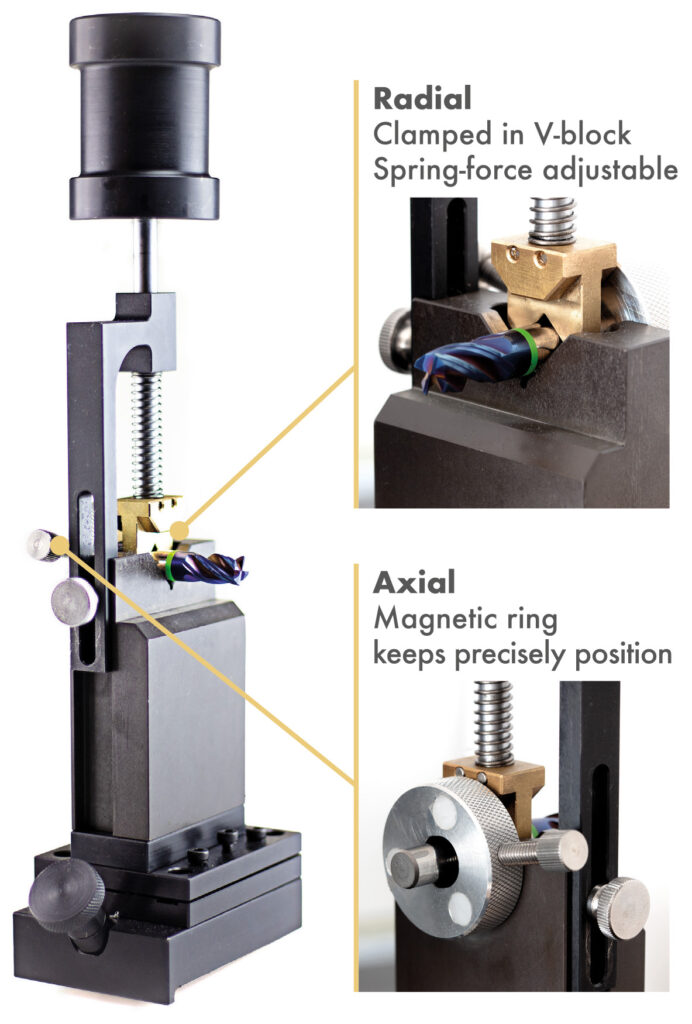

Ergonomic Design

Toollense is designed for user-friendly and comfortable handling.

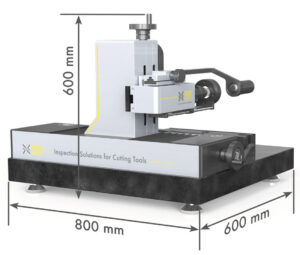

Massive Base for Maximum Precision

A massive base is essential for long-lasting precise measurements. Toollense is designed to meet these requirements: it is aligned exactly on three points and guarantees a foundation for long-term measurement accuracy and high reliability with its 7 cm thick, stable, and high-precision granite plate. Therefore, Toollense is ideal for precise requirements directly in the production or in the measurement room.

Service

Our machines are highly sustainable and require minimal maintenance. Should a service be necessary, we can initially provide quick support via remote maintenance to find uncomplicated solutions. If an on-site technician is needed, we can respond promptly from Urbach (closed by Stuttgart/Germany) and will be with you as soon as possible. Additionally, all necessary spare parts are available from stock. With us, you have a fair and reliable partner who is always there for you and on whom you can sustainably depend.