Application examples

With ToolLense, any cutting tool, such as milling cutters, drills, saw blades, disc cutters, whatever, can be measured easily and precisely.

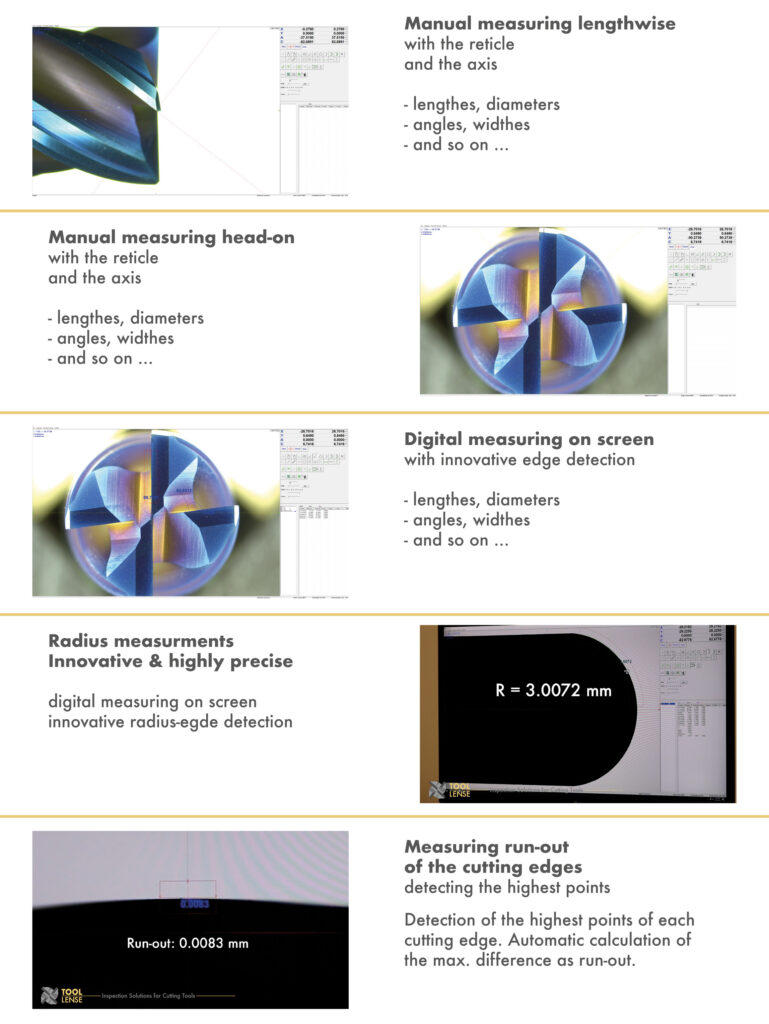

With the axes and the help of the crosshairs, measurements can be made easily and quickly. The crosshairs recognise edges and changes its colour. That makes measurement very easy for the user. Diameters, lengths, widths, distances or angles can be measured quickly, easily and with high precision.

ToolLense is particularly proud of its innovative and exceptionally precise edge detection. With the help of edge detection, edges can be determined and measured in a flash with a simple mouse click. Distances, angles on cutting tools such as milling cutters or drills can be easily determined according to specifications.

Another high-precision feature is the automatic radius edge detection. In combination with the feature for contour recording and precise clamping devices, radius measurements in the smallest µm-range are possible.

ToolLense simple determines run-out by finding the highest points of each cutting edge. Here again, edge detection and a precise clamping device play a major role in accuracy.

Comparison measurements according to CAD data or an image comparison directly on the screen are also possible, as is simple automation of the individual measurement processes in the image.

More information, please see our application video: